Full in-house operation.

BPC have full in-house, pre-treatment facilities for a wide range of metals, including a purpose built sandblasting booth, chromate-conversion dipping tanks and an on-line phosphate wash.

Once the correct pre-treatment has been undertaken, we have both a large batch oven measuring in at 7m long, and an 80m conveyor line, which allows our team to efficiently provide our customers with the highest quality finish.

We service commercial clients, and private customers, with large production runs, to small one-off’s.

With the largest powder coating spray booth and curing oven in Western Victoria, the team at BPC can handle even the largest of projects in their stride.

- Curing oven: 6.9m x 3m x 2.7m

- Spray booth: 12m x 3.5m

Our 80m conveyor line allows the team to efficiently powder coat a high volume of parts, whilst quick colour-changes also allow multiple small production runs of vast materials.

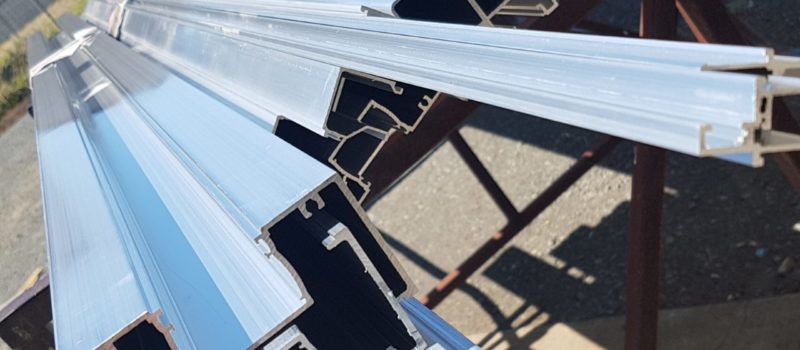

- Aluminium Extrusion upto 6.5m in length

- Parts upto 1450mm in height/drop

A new purpose-built sandblasting booth allows the BPC team to methodically clean and strip metal of rust, oxidation, paint and powder, and other manufacturing impurities, on both large and small parts.

- 9m(L) x 4m(W) x 3m(H)

BPC has a series of pre-treatment dipping tanks, for chromate conversion-coatings. We’ve found this system to be the most effective in providing corrosion protection, whilst also promoting adhesion.

- Dipping tanks: 8m long

- Ideal for aluminum extrusion, trims and complex parts

We also have a state-of-the-art, on-line (converyor) conversion coating system, ideal for cleaning, degreasing parts, prior to a spray-on phosphate conversion coating.

- Clean and Degrease, and Conversion coating

- Ideal for large production runs

NEED A QUOTE? Get in touch below….